1500L SUS316 Stainless Steel Sterile Water Tank for Pure Water

1500L SUS316 Stainless Steel Sterile Water Tank for Pure Water

The STARK 1500L stainless steel sterile water tank is a hygienic-grade pressureless vessel made from SUS316 stainless steel. Engineered for storing high-purity water, it is widely used in pharmaceutical cleanrooms, RO/EDI water systems, food and beverage processing, and biotech applications where hygiene and corrosion resistance are critical.

Featuring a vertical cylindrical structure with mirror-polished surfaces (Ra ≤ 0.4μm), this sterile tank minimizes contamination risk and supports CIP/SIP cleaning. The tank is lightweight yet durable, with a compact footprint for easy system integration. It is a reliable choice for hygienic water storage in clean and controlled environments.

The STARK 1500L stainless steel sterile water tank is a hygienic-grade pressureless vessel made from SUS316 stainless steel. Engineered for storing high-purity water, it is widely used in pharmaceutical cleanrooms, RO/EDI water systems, food and beverage processing, and biotech applications where hygiene and corrosion resistance are critical.

Featuring a vertical cylindrical structure with mirror-polished surfaces (Ra ≤ 0.4μm), this sterile tank minimizes contamination risk and supports CIP/SIP cleaning. The tank is lightweight yet durable, with a compact footprint for easy system integration. It is a reliable choice for hygienic water storage in clean and controlled environments.

The STARK 1500L Stainless Steel Sterile Water Tank is engineered to provide ultra-hygienic water storage in high-purity systems. Fabricated using premium SUS316 stainless steel, this tank resists corrosion, bacterial growth, and contamination. Its internal surfaces are mirror-polished to a Ra finish below 0.4μm, minimizing residue accumulation and ensuring maximum cleanliness.

This vertical cylindrical tank is fully TIG (Tungsten Inert Gas) welded by professional welders in a controlled environment, ensuring uniform weld seams with high mechanical strength and no dead angles. The tank body is constructed without internal crevices or rivets, which significantly reduces microbial adhesion and makes cleaning more effective. All welding joints are subjected to X-ray or penetration testing according to customer requirements.

It features a top-mounted vent port, CIP/SIP nozzle compatibility, and options for manhole and spray ball integration. The 1.5mm wall thickness delivers strength without compromising on weight, making it easy to install, relocate, or integrate into modular systems.

With standard inlet and outlet ports sized at 38mm, the tank supports quick integration into RO/EDI water treatment lines. Its compact footprint (Φ1200 × 2320 mm) is ideal for space-constrained environments such as cleanrooms and process skids. Whether used as a buffer tank or final product holding vessel, this sterile tank ensures reliable and hygienic water containment in every cycle.

Standard Accessories and Configuration

- Top vent port: For pressure balance and steam sterilization

- Inlet/outlet ports (38mm): DIN or tri-clamp standard, customizable upon request

- Polished inner surface: Ra ≤ 0.4μm, suitable for pharmaceutical use

- Pressure gauge socket: Optional installation on tank body

- Manhole: Optional DN400 inspection port for manual access

- Spray ball port: Compatible with CIP systems

- Legs/support base: Stainless steel adjustable supports for stable floor installation

Optional customization includes: flange/tri-clamp nozzles, insulation jackets, manholes, pressure gauges, and support stands. Each unit undergoes rigorous quality control and can be delivered with 3D drawing files and welding traceability upon request.

| Parameter | Value | Description |

|---|---|---|

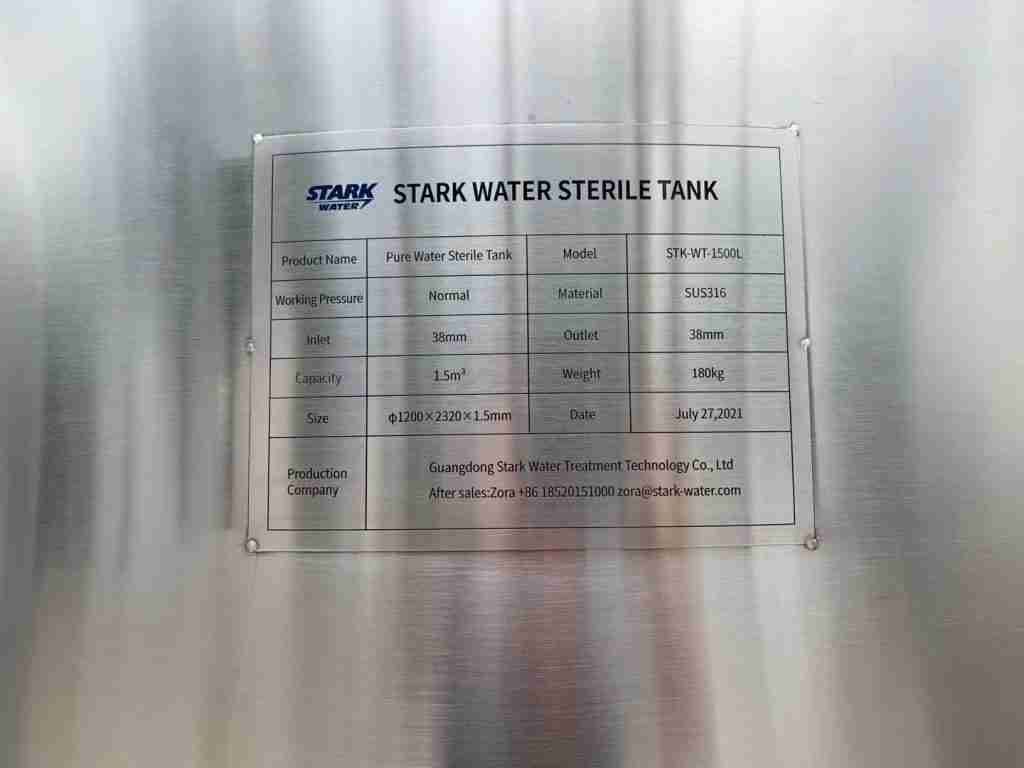

| Model | STK-WT-1500L | Internal code for 1500L sterile tank |

| Tank Capacity | 1500 Liters / 1.5 m³ | Effective liquid storage volume |

| Material | SUS316 Stainless Steel | Corrosion-resistant, hygienic-grade |

| Surface Finish | Mirror-polished (Ra ≤ 0.4μm) | Food-grade interior for clean operation |

| Wall Thickness | 1.5 mm | Optimized for strength and lightweight design |

| Dimensions | Φ1200 × 2320 mm | Tank diameter and total height |

| Weight | 180 kg | Dry tank weight for logistics calculation |

| Inlet/Outlet Size | 38 mm | Standard size for fluid connections (customizable) |

| Working Pressure | Atmospheric (Non-pressurized) | Designed for open or gravity-fed systems |

| Installation Type | Vertical, Floor-mounted | Equipped with stainless steel adjustable legs |

| Optional Accessories | Manhole, Spray Ball, CIP Port | Custom configuration available on request |

| Production Standard | ISO 9001:2015 / GMP compliant | Manufactured in clean assembly zone |

The 1500L Stainless Steel Sterile Water Tank is designed for critical applications where hygiene, corrosion resistance, and structural integrity are essential. It is particularly well-suited for the following industries and scenarios:

- Pharmaceutical Manufacturing: Used for storing purified water (PW) or water for injection (WFI) in cleanroom environments. Its mirror-polished surface prevents biofilm formation and supports strict GMP compliance.

- Food & Beverage Processing: Ideal for holding process water, ingredient water, or cleaning water in dairy, brewing, and beverage factories. The SUS316 construction prevents metallic ion release and ensures food safety.

- Biotechnology & Fermentation: Serves as a sterile buffer tank or intermediate holding vessel in enzyme production, vaccine lines, and fermentation systems requiring aseptic conditions.

- Laboratories & Research Facilities: Suitable for ultrapure water storage in analytical testing, life sciences, and chemical labs where contamination risk must be minimized.

- Electronics & Semiconductor Plants: Installed as part of UPW (ultra-pure water) loops in wafer washing, circuit board manufacturing, or LCD fabrication, ensuring ionic cleanliness and stability.

- Hospital & Dialysis Centers: Used to store RO-treated water for hemodialysis machines, with optional spray balls and disinfection ports for continuous microbial control.

- Water Treatment Skid Systems: Functions as a feedwater, buffer, or final-stage sterile holding tank within RO+EDI+UV water treatment systems. Easily integrated into modular process skids.

The STARK 1500L Stainless Steel Sterile Water Tank is engineered to provide ultra-hygienic water storage in high-purity systems. Fabricated using premium SUS316 stainless steel, this tank resists corrosion, bacterial growth, and contamination. Its internal surfaces are mirror-polished to a Ra finish below 0.4μm, minimizing residue accumulation and ensuring maximum cleanliness.

This vertical cylindrical tank is fully TIG (Tungsten Inert Gas) welded by professional welders in a controlled environment, ensuring uniform weld seams with high mechanical strength and no dead angles. The tank body is constructed without internal crevices or rivets, which significantly reduces microbial adhesion and makes cleaning more effective. All welding joints are subjected to X-ray or penetration testing according to customer requirements.

It features a top-mounted vent port, CIP/SIP nozzle compatibility, and options for manhole and spray ball integration. The 1.5mm wall thickness delivers strength without compromising on weight, making it easy to install, relocate, or integrate into modular systems.

With standard inlet and outlet ports sized at 38mm, the tank supports quick integration into RO/EDI water treatment lines. Its compact footprint (Φ1200 × 2320 mm) is ideal for space-constrained environments such as cleanrooms and process skids. Whether used as a buffer tank or final product holding vessel, this sterile tank ensures reliable and hygienic water containment in every cycle.

Standard Accessories and Configuration

- Top vent port: For pressure balance and steam sterilization

- Inlet/outlet ports (38mm): DIN or tri-clamp standard, customizable upon request

- Polished inner surface: Ra ≤ 0.4μm, suitable for pharmaceutical use

- Pressure gauge socket: Optional installation on tank body

- Manhole: Optional DN400 inspection port for manual access

- Spray ball port: Compatible with CIP systems

- Legs/support base: Stainless steel adjustable supports for stable floor installation

Optional customization includes: flange/tri-clamp nozzles, insulation jackets, manholes, pressure gauges, and support stands. Each unit undergoes rigorous quality control and can be delivered with 3D drawing files and welding traceability upon request.

| Parameter | Value | Description |

|---|---|---|

| Model | STK-WT-1500L | Internal code for 1500L sterile tank |

| Tank Capacity | 1500 Liters / 1.5 m³ | Effective liquid storage volume |

| Material | SUS316 Stainless Steel | Corrosion-resistant, hygienic-grade |

| Surface Finish | Mirror-polished (Ra ≤ 0.4μm) | Food-grade interior for clean operation |

| Wall Thickness | 1.5 mm | Optimized for strength and lightweight design |

| Dimensions | Φ1200 × 2320 mm | Tank diameter and total height |

| Weight | 180 kg | Dry tank weight for logistics calculation |

| Inlet/Outlet Size | 38 mm | Standard size for fluid connections (customizable) |

| Working Pressure | Atmospheric (Non-pressurized) | Designed for open or gravity-fed systems |

| Installation Type | Vertical, Floor-mounted | Equipped with stainless steel adjustable legs |

| Optional Accessories | Manhole, Spray Ball, CIP Port | Custom configuration available on request |

| Production Standard | ISO 9001:2015 / GMP compliant | Manufactured in clean assembly zone |

The 1500L Stainless Steel Sterile Water Tank is designed for critical applications where hygiene, corrosion resistance, and structural integrity are essential. It is particularly well-suited for the following industries and scenarios:

- Pharmaceutical Manufacturing: Used for storing purified water (PW) or water for injection (WFI) in cleanroom environments. Its mirror-polished surface prevents biofilm formation and supports strict GMP compliance.

- Food & Beverage Processing: Ideal for holding process water, ingredient water, or cleaning water in dairy, brewing, and beverage factories. The SUS316 construction prevents metallic ion release and ensures food safety.

- Biotechnology & Fermentation: Serves as a sterile buffer tank or intermediate holding vessel in enzyme production, vaccine lines, and fermentation systems requiring aseptic conditions.

- Laboratories & Research Facilities: Suitable for ultrapure water storage in analytical testing, life sciences, and chemical labs where contamination risk must be minimized.

- Electronics & Semiconductor Plants: Installed as part of UPW (ultra-pure water) loops in wafer washing, circuit board manufacturing, or LCD fabrication, ensuring ionic cleanliness and stability.

- Hospital & Dialysis Centers: Used to store RO-treated water for hemodialysis machines, with optional spray balls and disinfection ports for continuous microbial control.

- Water Treatment Skid Systems: Functions as a feedwater, buffer, or final-stage sterile holding tank within RO+EDI+UV water treatment systems. Easily integrated into modular process skids.